An Introduction to Corrugated Cardboard

What is corrugated cardboard? How is it made, and why should I choose it?

Check out our handy guide...

What is the difference between regular cardboard and corrugated cardboard?

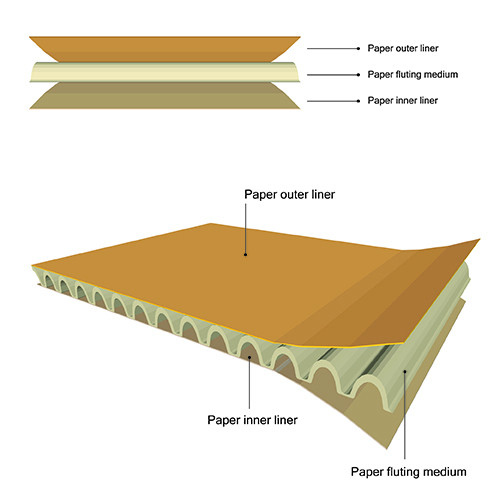

Cardboard that is typically found in greetings cards, craft stores, and food packaging usually refers to heavy paper-pulp or a thick paper stock. This cardboard is easily folded and formed, but doesn’t offer much product protection. Corrugated cardboard, on the other hand, is formed in three layers; and inner layer, an outer layer, and zig zagged fluting in between. This makes the corrugated cardboard more durable, offering a higher level of product protection.

Corrugated cartons are ideal for shipping and storage, whilst also being environmentally friendly due to their easily recyclable nature. In numbers, corrugated cardboard protects over 75% of goods in Europe, and 88% of it is made with recycled products. Corrugated cardboard is also one of the most extensively used materials in packaging with 43 billion m2 of board produced every year, to make everything from cardboard boxes, to edge protection, protective sheeting, and postal packaging.

How is corrugated cardboard made?

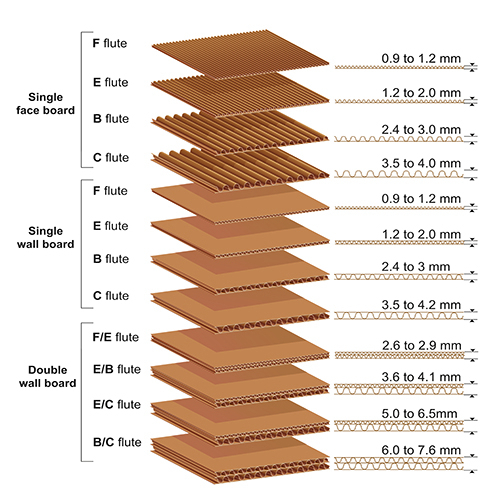

Corrugated cardboard is made using a starch glue to bond the inner and outer ‘liners’ with the fluting to give the board it’s structure. Double walled and triple walled cardboard is made by using one or two additional liners and layers of fluting respectively. The fluting structure is designed to support heavier weights and provide a higher level of resistance and rigidity, whilst the air that circulates around it provides insulation against temperature fluctuations. Fluting itself comes in a range of options, with the most popular for single wall cartons being B Flute, C Flute, or E Flute. Double and triple wall cartons often use a combination of these flutings, for example BC Flute and EB Flute (two common flutings for double wall cartons which combine B and C flute and B and E flute respectively).

Other important qualities to be taken into account when choosing corrugated board are the paper types in use, and the paper weights. There are two paper types that are commonly used in corrugated board, Kraft and Test. Kraft paper is made from a soft wood and provides a smooth quality finish, test paper meanwhile uses a slightly lower quality pulp and lacks the strength, shine and finish of the Kraft. For this reason, test paper is often used on as the interior paper layer when the strength is made up elsewhere in the board. One area that can provide additional strength is the paper weight, which is measured in grams per square meter (gsm) with common paper weights ranging from 115 to 300gsm.

Why choose corrugated?

Corrugated board is an affordable choice for most businesses, with low costs relating to a combination of high availability and low shipping costs. The ease of recycling cardboard also lowers the environmental impact of cardboard when compared to materials such as plastic, making the decision to choose corrugated both economically and ecologically beneficial.

Corrugated cartons come in a selection of sizes, styles and options, with a standard set of designs being set out and referred to using FEFCO codes. For cardboard boxes, the most common style uses the code 0201, which requires adhesive tape to seal. Meanwhile, postal boxes are a popular choice for eCommerce sites, with the most popular style being 0427 (otherwise known as a pizza box style). It is important to note that Corrugated Cartons are typically measured internally in the order of Length, Width, and Height (LxWxH).

The versatility of corrugated also makes it a great choice for customisation, with custom boxes being a great way to build brand awareness. The growing trend of unboxing is evidence of the impact that high quality custom packaging can have on the user experience. Customisation is also not limited to on-the-box design, but also includes custom sized packaging that is cut to fit a specific product or purpose (such as subscription postal boxes). Having a box that is shaped to fit means less void fill packaging is required, and is a big part of the consumer experience, with a greater number of retailers being called out online for excessive or poorly sized packaging.

Overall, corrugated cardboard is one of the most versatile packaging products, and the rise of environmentally friendly packaging only increases its popularity. From simple removal or shipping boxes, to custom designed postal boxes and book wraps, corrugated cardboard has been in use for over 150 years and, thanks in part to closed loop recycling, its usage continues to grow.