What is Gummed Paper Tape?

Gummed Paper Tape has been rapidly increasing in popularity over recent years due to its near-perfect environmental credentials and superior packaging performance, but what is Gummed Paper Tape, and why should you consider using it?

Gummed Paper Tape has been rapidly increasing in popularity over recent years due to its near-perfect environmental credentials and superior packaging performance, but what is Gummed Paper Tape, and why should you consider using it?

What is Gummed Paper Tape?

Gummed Paper Tape is also sometimes referred to as water activated tape, as the natural glue adhesive becomes sticky when moistened, allowing it to strongly adhere to the box. The water activation allows the tape to penetrate the fibres of the cardboard, becoming an integral part of the box whilst also creating a tamper-proof seal that is resistant to environmental fluctuations. Gummed paper tape is available with either a traditional brown Kraft backing, a white Kraft backing, or it can be easily printed on to showcase your brand.

Gummed Paper Tape can be produced with either the gummed side in or out (identified as GSI or GSO on our website), which determines which side of the role is coated in adhesive. The most conventional option is GSI, wherein the tape is wound onto the roll with the adhesive facing inwards, however some users prefers to use tape that is wound GSO. This choice between GSI and GSO is purely down to personal preference and has no bearing on the performance or ease of use of the tape.

For additional carton strength and rigidity, alongside a higher pilfer-resistance, we also offer Reinforced Gummed Paper Tape. This tape is reinforced with cross woven glass fibres that are bonded between the high-tensile sheets for additional strength, and to enhance the burst-resistance.

Why use Gummed Paper Tape?

Strong

Gummed paper tape is made from two layers of Kraft paper alongside a layer of natural rubber adhesive. When the glue adhesive comes into contact with water, it creates a complete bond with the carton by penetrating the liner, thus making it a part of the box itself. This can help make the parcel significantly stronger and more secure.

Tamper Evident

Due to the way in which gummed paper tape is attached to the box, any attempt to separate the two results in damage to the carton, providing evidence of any tampering that may have occurred. Once the tape has been interfered with, it cannot be resealed either, therefore ensuring that any intrusion is obvious immediately upon receiving any parcel. This tape can also serve as a deterrent against tampering during the delivery process.

Temperature Tolerant

Unlike traditional plastic tapes that can lose their seal quality when subjected to varying temperatures, the way in which gummed paper tape is sealed to the carton ensures that it has the ability to withstand a wide range of temperatures. Gummed paper tape is also well performing in high humidity and freezing conditions, ensuring that it binds well regardless of the conditions that it is applied, stored, and transported in. Our gummed paper tape is also highly resistant to aging, making it perfect for long-term storage in any environment.

Cost Effective

Whilst gummed paper tape has a significantly higher upfront cost in comparison to traditional packaging tape, most of these costs are associated with purchasing dispensers. Gummed paper tape is more cost effective in the long term, as only the required length of tape is dispensed, and each parcel requires only a single strip of tape to be fully sealed and pilfer proof. The use of gummed paper tape is also more beneficial as it decreases the chances of lost or damaged products, and therefore can help to save money by reducing returns and replacements.

Environmentally Conscious

Gummed paper tape is made up of entirely renewable natural resources that are also fully recyclable and biodegradable. These elements allow for it to be left on the carton, and the two can be disposed of together. The tape is also completely solvent free, allowing the gum to break down easily for recycling. Many companies have decided to switch to gummed paper tape in order to boost their green credentials and improve their environmental consciousness, appealing to a wider range of increasingly aware customers.

Efficient

When used with a tape dispenser, particularly an electronic one, only the exact amount of tape is dispensed to seal the parcel. This helps to prevent any unnecessary packaging waste, whilst also speeding up the packing process and reducing the occurrence of operator fatigue, particularly for medium- to high-volume users.

Professional

An incredibly important benefit to using paper tape is that it is a lot more visually appealing than its counterparts. The single strip of gummed paper tape makes any parcel look significantly more neatly presented, and the cleaner look can provide a more satisfying unboxing experience. A package sealed with gummed paper tape is guaranteed to look neater and more professional, positively reflecting both your product, and your brand as a whole.

Customisable

Another great benefit to gummed paper tape is that it is very easy to print on, further adding to the customer’s unboxing experience. The use of a single strip of tape for sealing also guarantees that your brand’s image will take centre stage on the box, and there won’t be any overlap of additional tape (as you would get when using a traditional packaging tape).

How to use Gummed Paper Tape

Gummed Paper Tape requires a specific Paper Tape Dispenser. These are available as either a manual model, or an electronic model.

Manual Dispensers

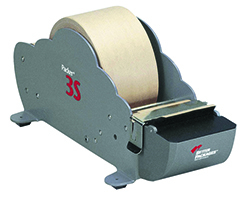

Manual Dispensers are an economical option for low volume users with smaller budgets, and operate using either a pull and tear mechanism, or lever-stroke operation. The most basic of our manual dispensers (the EPS80 and 3S) operate by the user pulling the tape across a wet surface and then tearing the tape to the preferred length. Our mid-range manual dispenser (BP333) automatically wets the tape for the user, and distributes a set tape length per lever stroke, ensuring uniform tape wetting and cutting. An important aspect to consider when purchasing a tape dispenser is not only your usage, but also power requirements and availability, with manual dispensers having no need for a power supply and therefore being suitable for use anywhere.

Electronic Dispensers

Electronic Dispensers have a significantly higher output capacity for higher volume usage, leading to greater productivity and efficiency. Electronic dispensers are very easy to use, and can dispense a set length of tape consistently. Both of our Electronic models (the BP500 and BP555) have colour coded pre-set keys that feature popular tape lengths for increased user-friendliness, and the exact cutting helps to ensure that there is no excess waste produced. For business with higher usage rates, this is a great investment, and a definite money (and time) saver in the long term.